Which epoxy yellows the least? That is a common question. This guide compares epoxy brands on yellowing over time, so you can choose the right resin for your project with more confidence.

Important up front: no epoxy stays perfectly colorless forever. You can, however, slow yellowing down significantly with the right resin and workflow.

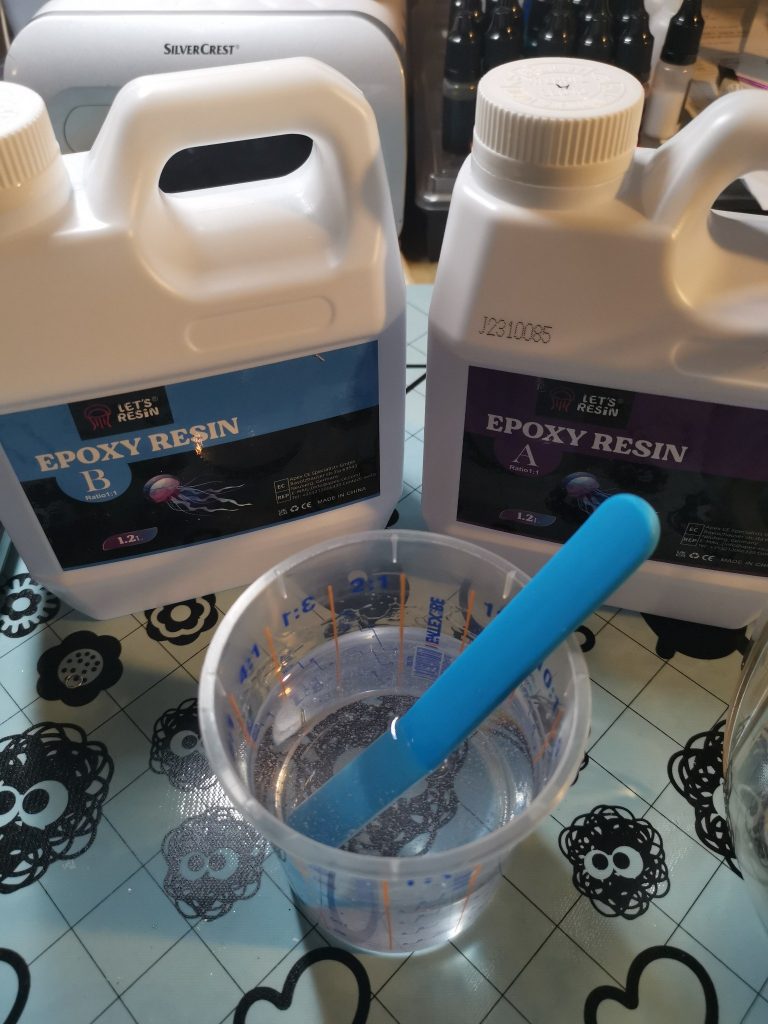

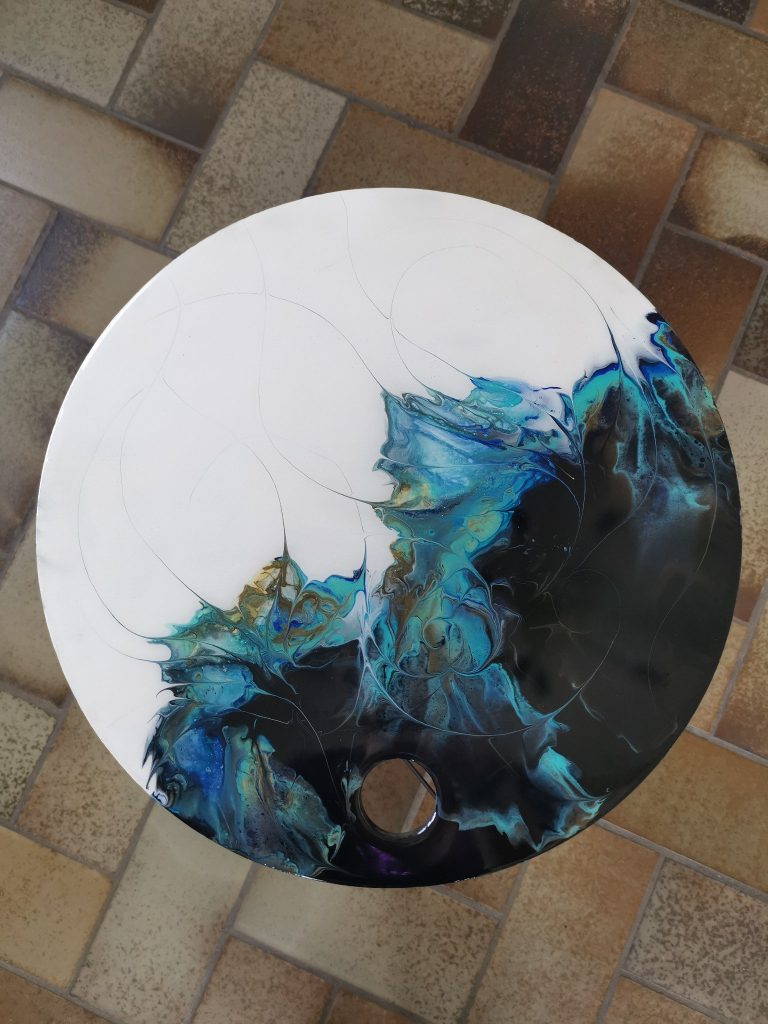

My practical experience with Let’s Resin

My experience with Let’s Resin has been very positive: I made multiple jewelry pieces over several years, and they did not show visible discoloration. Conditions still matter (light, heat, use), but in my own projects this brand has been very stable.

Why does epoxy yellow over time?

- UV exposure (including through windows) gradually degrades resin chemistry.

- Heat accelerates aging and oxidation.

- Oxidation during storage and after cure.

- Overly thick pours or overheating while curing can speed discoloration.

- Wrong mix ratio or poor mixing can reduce cure stability.

What accelerates yellowing most?

- Direct sunlight and high daylight exposure.

- High ambient temperature and warm placement.

- Too large a batch or too thick a pour for the system.

- Using non-UV-stabilized systems in high-light applications.

- Poor storage of components before use.

What can slow yellowing down?

- Choose UV-stabilized epoxy for clear applications.

- Stay within layer-thickness limits and pour in controlled stages.

- Keep process temperature stable and avoid cup exotherm spikes.

- Protect finished work from prolonged direct sunlight.

- Use a UV-stable topcoat where light load is high.

Which brands yellow the least?

This is a practical selection guide based on public product positioning (UV stability) and observed behavior in creative use cases, not a lab ranking.

Often strongest for long clear appearance

- Let’s Resin (UV-resistant lines)

- ArtResin

- EPODEX PRO / PRO+

Can perform well but more condition-sensitive

- Mr Boat (depends strongly on project depth and heat)

- EPODEX ECO (generally less UV-focused than PRO lines)

Realistic expectation

Even premium systems can yellow eventually. The key difference is usually how fast that becomes visible.

Quick checklist

- UV-stabilized resin selected?

- Exact ratio mixed?

- Layer thickness within spec?

- Direct sun exposure limited?

- Need for UV topcoat evaluated?

Continue Reading on Creadeliefje

For more resin guides, check our in-house articles on casting, finishing, and long-term clarity.